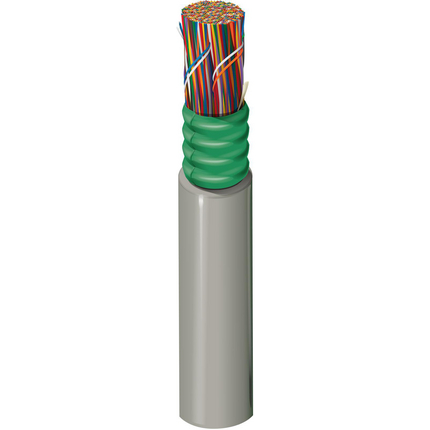

Product Overview

| Suitable Applications: |

Premise Backbone Cable |

Physical Characteristics (Overall)

| AWG |

Stranding |

Material |

No. of Pairs |

| 24 |

Solid |

BC – Bare Copper |

300 |

| Total Number of Pairs: |

300 |

| Material |

| PO – Polyolefin (Foam) |

| Number |

Color |

| 1 |

White & Blue |

| 2 |

White & Orange |

| 3 |

White & Green |

| 4 |

White & Brown |

| 5 |

White & Slate |

| 6 |

Red & Blue |

| 7 |

Red & Orange |

| 8 |

Red & Green |

| 9 |

Red & Brown |

| 10 |

Red & Slate |

| 11 |

Black & Blue |

| 12 |

Black & Orange |

| 13 |

Black & Green |

| 14 |

Black & Brown |

| 15 |

Black & Slate |

| 16 |

Yellow & Blue |

| 17 |

Yellow & Orange |

| 18 |

Yellow & Green |

| 19 |

Yellow & Brown |

| 20 |

Yellow & Slate |

| 21 |

Violet & Blue |

| 22 |

Violet & Orange |

| 23 |

Violet & Green |

| 24 |

Violet & Brown |

| 25 |

Violet & Slate |

| Group One Binder |

White/Blue |

| Group Two Binder |

White/Orange |

| Group Three Binder |

White/Green |

| Group Four Binder |

White/Brown |

| Group Five Binder |

White/Slate |

| Group Six Binder |

Red/Blue |

| Group Seven Binder |

Red/Orange |

| Group Eight Binder |

Red/Green |

| Group Nine Binder |

Red/Brown |

| Group Ten Binder |

Red/Slate |

| Group Eleven Binder |

Black/Blue |

| Group Twelve Binder |

Black/Orange |

| Number |

| 1 |

| 2 |

| 3 |

| 4 |

| 5 |

| 6 |

| 7 |

| 8 |

| 9 |

| 10 |

| 11 |

| 12 |

| Material |

Nominal Diameter |

Ripcord |

| PVC – Polyvinyl Chloride |

1.320 in |

Yes |

Construction and Dimensions

| Type of Armor |

Material |

Thickness of Armoring Tape |

| Corrugated |

Aluminum |

.008 in |

Electrical Characteristics

| Max. Conductor DCR |

Max. DCR Unbalance |

| 93.8 Ohm/km |

5 % |

| Max. Capacitance Unbalance |

Nom.Mutual Capacitance |

| 330 pF/100m |

17 pF/ft |

| Frequency [MHz] |

Max. Delay |

Max. Delay Skew |

Nominal Velocity of Propagation (VP) [%] |

| 16 MHz |

543 ns/100m |

45 ns/100m |

68% |

| Frequency [MHz] |

Max. Insertion Loss (Attenuation) |

Min. NEXT [dB] |

Min. PSNEXT [dB] |

Min. ACR [dB] |

Min. PSACR [dB] |

Min. RL (Return Loss) [dB] |

Max./Min. Fitted Impedance |

| 0.772 MHz |

2.2 dB/100m |

47.0 dB |

43.0 dB |

50.1 dB |

46.1 dB |

|

100 +/- 15 |

| 1.0 MHz |

2.6 dB/100m |

45.0 dB |

41.0 dB |

47.8 dB |

43.8 dB |

12.0 dB |

100 +/- 15 |

| 4.0 MHz |

5.6 dB/100m |

36.0 dB |

32.0 dB |

36.0 dB |

32.0 dB |

12.0 dB |

100 +/- 15 |

| 8.0 MHz |

8.5 dB/100m |

31.0 dB |

27.0 dB |

28.3 dB |

24.3 dB |

12.0 dB |

100 +/- 15 |

| 10.0 MHz |

9.7 dB/100m |

30.0 dB |

26.0 dB |

26.2 dB |

22.2 dB |

12.0 dB |

100 +/- 15 |

| 16.0 MHz |

13.1 dB/100m |

27.0 dB |

23.0 dB |

20.1 dB |

16.1 dB |

10.0 dB |

100 +/- 15 |

| UL Voltage Rating |

| 300 V RMS |

Temperature Range

| Installation Temperature Range: |

-20°C To +60°C |

| Storage Temperature Range: |

-30°C To +60°C |

| Operating Temperature Range: |

-30°C To +60°C |

Mechanical Characteristics

| Bulk Cable Weight: |

1104 lbs/1000ft |

| Max. Pull Tension: |

1800 lbs |

| Min. Bend Radius During Installation: |

26.5 in |

| Min. Bend Radius/Minor Axis: |

13.25 in |

Standards

| CEC/C(UL) Compliance: |

CMR |

| Data Category: |

Category 3 |

| ANSI Compliance: |

S-90-661-2012 Category 3, ANSI/NEMA WC-63.1 Category 3 |

| TIA/EIA Compliance: |

ANSI/TIA-568-C.2 Category 3 |

Applicable Environmental and Other Programs

| Environmental Space: |

Riser |

| EU Directive 2000/53/EC (ELV): |

Yes |

| EU Directive 2003/96/EC (BFR): |

Yes |

| EU Directive 2011/65/EU (RoHS 2): |

Yes |

| EU Directive 2012/19/EU (WEEE): |

Yes |

| EU Directive 2015/863/EU (RoHS 2 amendment): |

Yes |

| EU Directive Compliance: |

Yes |

| EU REACH SVHC Compliance (yyyy-mm-dd): |

2017-07-10 |

| MII Order #39 (China RoHS): |

Yes |

Suitability

| Suitability – Hazardous Locations: |

No |

| Suitability – Indoor: |

Yes |

| Suitability – Non-Halogenated: |

No |

| Suitability – Oil Resistance: |

No |

| Suitability – Outdoor: |

No |

| Suitability – Sunlight Resistance: |

No |

Flammability, LS0H, Toxicity Testing

| CSA/C(UL) Flammability: |

FT4 |

| UL Flammability: |

UL 1666 Riser |

| UL voltage rating: |

300 V RMS |

Plenum/Non-Plenum

Related Part Numbers

| Item # |

Color |

Put-Up Type |

Length |

UPC |

| ATMM300 008CUT |

Gray |

Cut to Length |

|

612825062028 |

| ATMM300 008CUT |

Gray |

Cut to Length |

1 ft |

612825062028 |

Product Notes

| Notes: |

Electrical values are expected performance based on cable testing and representative performance within a typical Belden system. Print Includes Descending Footage/Meter Markings. Corrugated Aluminum Armor Bonded to the Jacket. |

History

| Update and Revision: |

Revision Number: 0.385 Revision Date: 12-20-2022 |